Productstream Professional successor? Compare.

Even years later, some users are still looking for a new PDM software as a PSP successor.

A PSP alternative with which they can also manage their product data in the future with at least the same level of quality.

Update February 2021

On 30.04.2021 the support of the DEX Migration Tool by Autodesk ends.

Autodesk is switching product licensing to Named user.

- You will no longer receive support for DEX as of 01.05.2021.

- Multi-user subscriptions will not be renewed after 07/08/2022.

Tip:

Switch to GAIN Collaboration now. As a former PSP user, you will quickly and easily find your way around it. Includes floating licenses for multiple users and many other benefits.

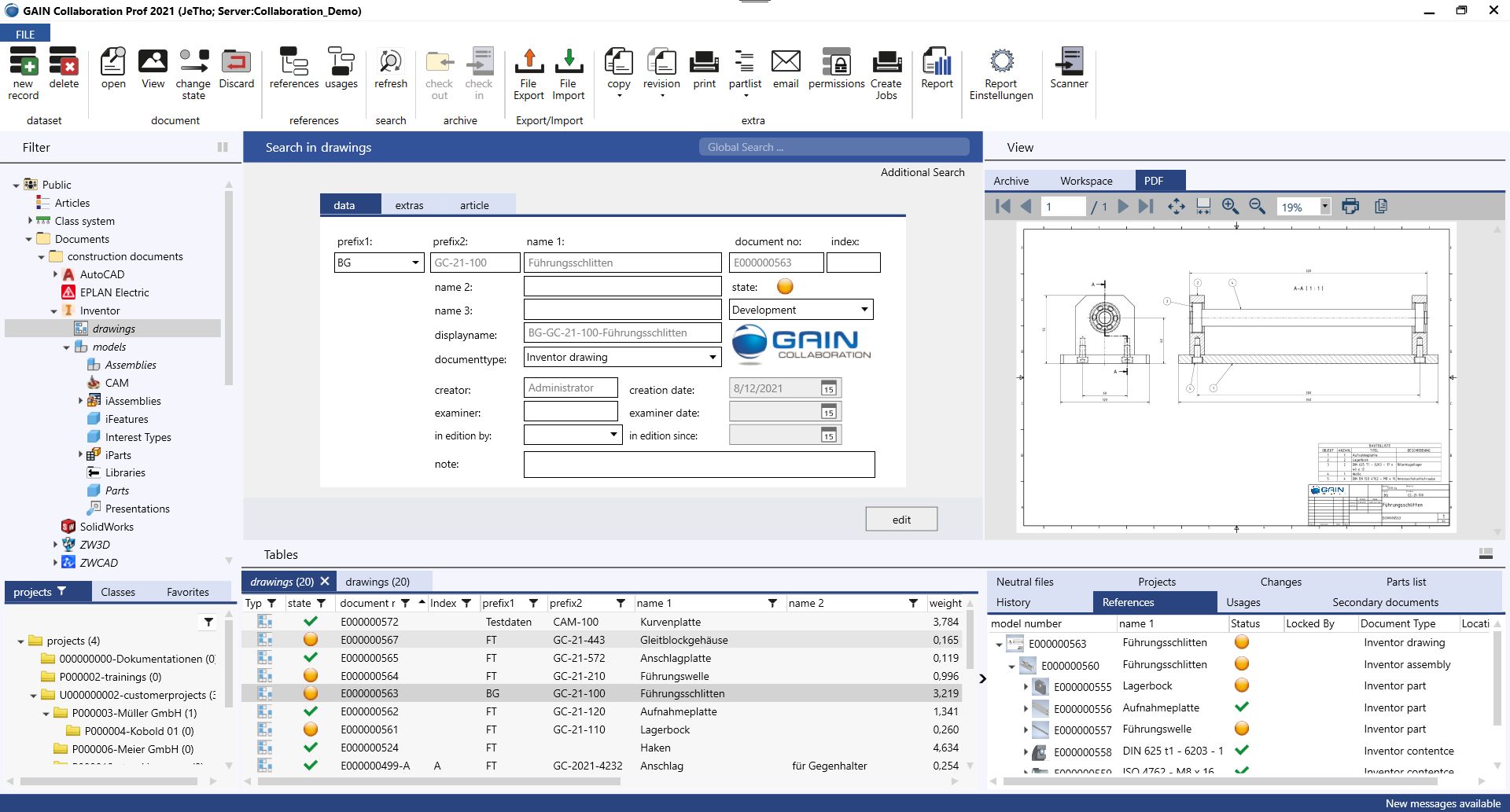

PSP successor with similar interface as Productstream Professional

Be it the view of projects or office documents: PSP and GAIN Collaboration are very similar.

Functions & Features: Compare

GAIN Collaboration as PSP successor preserves many of your PDM habits. In addition, you benefit from numerous practical and time-saving functions. Learn more about the features of PSP and GAIN Collaboration in comparison …

Opinions of former users of Compass Drawing Management

Of course, the thought of switching to PDM is not easy and needs to be thought through.

Find out what design engineers say about GAIN Collaboration as PSP successor …

What users say about the PSP successor GAIN Collaboration

"According to Productstream Professional, GAIN Collaboration meets all expectations."

Patrick Störmer, promark automation

Product data management for a characterizing company

Whenever reliable marking of metals, plastics or other materials is required, promark automation is an experienced partner. The team of experts from Eigeltingen on Lake Constance already had extensive experience in marking and printing technology before it was founded 7 years ago. Today promark automation realizes markings via laser, inkjet printer and other methods. The marking technology is used as a stand-alone solution or integrated directly into production machines in the automotive, extrusion, medical or aerospace sectors.

Switch from Productstream Professional to the PSP successor GAIN Collaboration

Due to the upcoming discontinuation of Autodesk Productstream Professional (PSP), promark automation had been looking for an adequate PSP successor for quite some time.

“The more similar and functional the new solution is to Autodesk PSP, the better,” recalls Patrick Störmer, design engineer and PDM system administrator. “That’s when GAIN Collaboration, with its interface very similar to PSP, caught our eye right away.”

Störmer: “The changeover to GAIN Collaboration only took three or four days. Before the changeover, we migrated all Inventor data to the Inventor version R2015 that we use, i.e. we updated it.

That was a very good control for us. On the one hand, this allowed us to check the quality of our data. On the other hand, this gave us the best conditions for transferring the data to the new PDM system without errors or losses.

The changeover to the PSP successor took place in two steps. The first step was to transfer the metadata from the PSP database to GAIN Collaboration. And without any loss. The second step was the transfer of our actual documents, such as the Inventor data into the archive directory of GAIN Collaboration.

These migration steps ran through overnight and the next morning all data was available in GAIN Collaboration. Without exception, all data were taken over in their original quality. We are very satisfied with the result. Especially since everything was handled in such a short time,” says Störmer.

Management of CAD, MS-Office documents and neutral data

A marking machine from promark automation as a stand-alone solution consists of a basic assembly with an average of 200 – 300 parts. These are composed of a frame and – depending on the application – various purchased parts in step format. In addition, there are production parts such as bent sheet metal parts or milled parts.

Currently about 40,000 documents are stored machine-related with GAIN Collaboration – primarily Autodesk Inventor and Step formats.

“Since we worked with Autodesk Productstream Easy before GAIN Collaboration, managing MS Office documents was not possible until now. Now we can also gradually store MS Office data on the projects. For example, data sheets in PDF or calculations in Excel format,” explains Störmer.

Current CAD workstations and prospects for the future

Currently two CAD workstations are equipped with GAIN Collaboration Professional. Patrick Störmer: “After a longer test phase, we want to equip various office workstations in sales and administration with GAIN Collaboration Office. Just in case you want to look something up. Moreover, everyone could then use the search and filing functions of GAIN Collaboration.”

In order to be able to profit from complete bills of materials, the Eigeltinger plan to equip two existing E-Plan workstations with corresponding interfaces. “Then, at the end of the day, we can generate a complete parts list at the push of a button. And then simply order the required electrical and mechanical parts efficiently. The all-round happy solution, so to speak,” smiles Störmer.

Simple processes with suppliers

Up to now GAIN Collaboration has only been used internally. Suppliers are currently not yet granted access to the PDM system. Until this happens, promark automation likes to use one or the other job server function of GAIN Collaboration. For example, the automatic creation of PDF files for suppliers. Störmer: “For binding order templates, we simply let GAIN Collaboration export parts lists to MS Excel. And for repeat orders or spare parts, GAIN Collaboration quickly and conveniently lists the corresponding part numbers for us.”

Highly appreciated: handling and operation

The marking professionals find the operation of the new PDM system very intuitive and clear:

Störmer: “You really find your way around GAIN Collaboration very quickly. Quasi intuitively. Our familiarization time was also very short. Files can be easily dragged and dropped directly into GAIN Collaboration. And then there are the numerous, flexible configuration options: You can change something on the fly yourself. That’s very practical,” says Störmer. “I also really appreciate the data screens, which I can easily customize myself. For example, GAIN Collaboration only shows me the information I really need. Not to forget: The search function. It’s very easy to use and helps us find the right components extremely quickly.”

Thanks to the administrator training, Patrick Störmer was able to make some personal optimizations to his search mask himself without further ado.

Familiar and faster: The Inventor interface

“The GAIN Collaboration Inventor interface is really cool,” says Störmer. “And since you work locally, it’s also much faster than we were used to. In the interface, we find the same tools that we had in PSP. For example, for replacing components with a copy or revision. Or that we can simply drag and drop components from GAIN Collaboration into Inventor and open them during the design process. Also the handling of frame generator parts is simple. GAIN Collaboration automatically sets the display name for the documents in Inventor. So we can finally see directly in the Inventor browser by the display name and number which parts are contained in an assembly. And creating drawings for models is now much easier. Here we only have to transfer the newly created drawing in Inventor to GAIN Collaboration, i.e. connect it. In the entry all information is then taken over from the model. Fully automatically. And if we should ever make a mistake here, it is quickly corrected via GAIN support,” says Störmer.

PSP successor with best service and support

They are also very satisfied with the performance, responsiveness and reliability of GAIN support.

“It really works very well. The support team always thinks along with us and usually solves problems directly on the phone. Or we receive direct feedback as to when we can expect a response,” says Störmer with satisfaction.

Even special requests have already been realized by GAIN Software quickly and unbureaucratically. For example, the automatic export of drawing sets at the push of a button while working. Or the user interfaces, which now look exactly as promark automation would like them to.

Changeover as an ascent

The bottom line is that the switch from Product stream Professional to the new PDM system GAIN Collaboration was a real step up for the Eigeltinger.

Patrick Störmer: “GAIN Collaboration meets all our expectations in terms of functionality, overview and ease of use. Many things have become easier. And we will be even more productive when our further PDM plans are also implemented with GAIN Collaboration.”

"GAIN Collaboration as the Autodesk PSP successor was an obvious choice for us."

Lars Marbacher, MSD Werthenstein

“Several thousand CAD drawings under Productstream Pro …”

MSD Werthenstein BioPharma GmbH, based in Schachen, Switzerland, is part of the MSD Group, which in turn is a subsidiary of the Merck pharmaceutical group. MSD is active in research and development for new medicines in over 140 countries. In Schachen, MSD Werthenstein prepares and manages the construction plans for the Schachen branch. They include 2D drawings in DWG format and most of them have external references such as further drawings, pictures and also MS Office documents. “That’s several thousand CAD drawings that we need to access as quickly and flexibly as possible,” explains Lars Marbacher, FM Technician Building Efficiency Global WorkPlace Solution at MSD Werthenstein. MSD Werthenstein have replaced AutoCAD® with ZWCAD from the company ZWSOFT Schweiz GmbH. “The feature set is no different than AutoCAD®,” says Marbacher, “however, ZWCAD’s licensing costs are much more affordable.”

Achieved the goal: Maintain familiar user habits

“The decision to use GAIN Collaboration to replace the former Autodesk Compass drawing management system was not a difficult one for us,” says Marbacher. “Especially since GAIN Software was the only vendor in the world that could provide us with an interface to ZWCAD, which we just switched to,” Marbacher says.

“GAIN Collaboration is quite similar to Autodesk Productstream Professional (PSP) in many places in terms of the general way it works. For example, the surface with its window arrangements. The search option across all properties, the maintenance of the article master data and where-used lists also remain the same in principle. Compared to Productstream Pro, the GAIN solution is much more modern. The clear user interface allows direct access to documents as well as search and filter functions. Details such as history, references, usage, etc. are clearly displayed for each file.”

Open for international cooperation and different CAD systems

GAIN Collaboration can also hold its own in national and international data exchange with its multilingual capabilities thanks to UNICODE and dictionary, in addition to the project management, definition of workflows and replication to other locations that are familiar to PSP.

Simpler, faster and more flexible PSP successor

The PSP alternative brings together previously incompatible data from different applications such as SolidWorks or Autodesk with Office documents. Design, product and accounting documents can be stored in a project together with the associated e-mails. “For example, if I insert an image into a drawing, I can simply drag and drop the image file into GAIN and couple it to the project,” Marbacher explains. The import is not only possible from applications but also from the Windows Explorer. GAIN Collaboration automatically detects the file format and inherits the existing properties, relationships and references.

The multi-processor technology together with GAIN Collaboration’s multithreading ensures fast opening and editing even of large files. Says Marbacher, “Multiple PDM processes can run in parallel because GAIN Collaboration distributes its performance demands across multiple processor cores.”

Simple: The graphical configuration

To meet the different needs of each organization, GAIN Collaboration can be configured for customization with graphical tools. This includes, for example, the user interface, toolbar, database, masks and status definitions (workflows).

Open for the future and secure investments

Peter Schmitt, owner and CEO of GAIN Software: “With its focus on performance, transparency, data security and flexibility, GAIN Collaboration is one of the most modern and fastest EDM/PDM systems on the market. The technology used in GAIN Collaboration is forward-looking: programmed with C-Sharp and based on the .NET framework, the GAIN Collaboration system meets the requirements and prerequisites for future generations of the Microsoft operating system. The user benefits from long-term investment security.”

The server-based system of GAIN Collaboration is based on an MS-SQL database architecture. While MSD with Productstream Professional (PSP) directly accessed the file server (archive) to open files, the access to documents with GAIN Collaboration as PSP successor is done via “Check-In/Check-Out”. GAIN Collaboration first saves the file in a workspace on the user’s computer. From there it is opened with ZWCAD. The advantage: The file can be viewed by other users, but cannot be changed during editing.

Fast implementation and data migration

At the beginning of 2015, MSD Werthenstein replaced Autodesk® Productstream® Professional with GAIN Collaboration. During the migration, the metadata was transferred from PSP 1:1 to GAIN Collaboration. A total of 8,000 documents, including approximately 6,000 2D drawings with external references, were transferred. The rest of the data consisted of Excel, Word, PDF and image files.

“GAIN Collaboration makes product data management much easier for us,” concludes Marbacher. Data exchange between individual user groups within the company is easier, because standard document types can be managed, organized and edited directly in GAIN Collaboration. All work steps are easily traceable, which means that the causes of errors can be found and eliminated quickly. With the EDM/PDM solution from GAIN Software GmbH as PSP successor or product stream, MSD Werthenstein is also comprehensively equipped for future requirements.

3 other former PSP users interviewed in DIGITAL ENGINEERING

GAIN Collaboration preserves your PDM habits and offers additional added value. Compare:

Data storage / Access PSP

- Data storage in the Windows file system

- No cryptic data encryption by renaming files

Data storage / access GAIN Collaboration

- Article master data maintenance

- Sealed archive

- Teamwork: check-in / check-out, current provision of data

- File protection by certificate (SSL encryption)

- High data security / no Windows release necessary

User interface PSP

- User interface with tables, record windows, folder structure

- Configurable folder structures

- document preview

- Search via search window

- Column filter

User Interface GAIN Collaboration

- Multilingualism

- Dictionary

Application PSP

- Drag & Drop: data import and document linking

- Structure copy/revision

- Status management

- Replication to other locations

Application GAIN Collaboration

- Deep, fine integration in programs

- Messaging system

Article and parts lists PSP

- Article master data maintenance

- CAD parts lists: Article supplement

- Manual addition of CAD parts list

- Assignment of documents to articles via drag & drop

- CAD and article parts list management

Article and parts lists GAIN Collaboration

- Export of parts lists

Project management PSP

- Creating projects

- Create subprojects

- Link documents to projects

- Create documents for projects

Project Management GAIN Collaboration

- Project Map Export

Audit management PSP

- Simple revision management: components, assemblies, drawings

- Copy revision or simple revision (increase of the index)

- List of changes

- Automatic status management

Audit Management GAIN Collaboration

- Notification system

Administration PSP

- Definition of workflows

- Automation of processes via job server

- Name catalogue

- Classification

- Interface configuration

- Programming interface

- ERP coupling

Administration GAIN Collaboration

- Graphical configuration menu

- Fast installation / deployment of GAIN Collaboration

- Update functionality

- Automatic neutral format setting

- Fast data migration for CAD version changes

- Graphical status editor

- Graphical database editor for SQL database

Technologies PSP

- client-server architecture

- Office and View modules

Technologies GAIN Collaboration

- C# program code

- .NET framework

- Multiprocessor technology

- WCF/WPF Technology

- Support for all Windows versions (7,8,10)

Program modules / interfaces PSP

- Professional, Office and View variants

- Replication across multiple sites

- Job server

- Interfaces to Autodesk products (Autodesk Inventor, AutoCAD …)

Program modules / interfaces

GAIN Collaboration

- Plot Manager

- Other CAD interfaces: SolidWorks, ZWCAD, BricsCAD, EPLAN, ZWCAD and ZW3D.

10 Advantages with GAIN Collaboration

1. 30 years of experience in one product

2. high investment security

3. increased product quality

4. multi CAD capable

5. simple, flexible and safe

6. individually adaptable

7. high data security

8. archive unencrypted and inaccessible

9. modern technology

10. attractive price-performance ratio

Test the migration from Autodesk PSP to GAIN Collaboration

Before implementing GAIN Collaboration as a PSP successor, you can test GAIN Collaboration at your leisure:

1. we first analyze your current environment (files, storage).

2. record your PDM wishes and goals.

3. then we coordinate all relevant key data with you.

4. we preconfigure your requirements internally.

5. and provide an environment for you to test.

6. once the tests have been passed, the company-wide rollout can begin.

With some background knowledge you can install and configure GAIN Collaboration on a server and the desired workstations (clients) yourself.

Your 1st step to GAIN Collaboration. Order a free demo:

Or do you have any questions

to GAIN Collaboration?

Please contact us: +49 521 967 613 – 0