How you can use ERP and PDM to PLM concept in flow

The exchange between ERP and PDM:

For the greatest initial PLM value creation

Product data management (PDM) and enterprise resource planning (ERP) form the backbone of initially digital and then physical product creation. By integrating ERP PDM and separating these autonomous systems from each other, all PLM information for stringent product development can be obtained from ERP and PDM.

The PDM system:

Virtual product data …

A PDM (Product Data Management) system helps companies develop their virtual prototype. From the initial design, to CAD designs, to specifications for manufacturing. Numerous product data are thus stored, shared and organized in the course.

Product data (examples):

- Product description, appearance and function

- Design data from CAD applications

- Product characteristics such as material, coating or weight

- Metadata of articles or parts lists

- Graphics, product descriptions, maintenance and electrical plans

- Product development statuses such as creation or test date

The ERP system:

… for the material reproduction

The ERP (Enterprise Resource Planning) system accesses the virtual product data for planning and controlling the production of these products. In the ERP, for example, the bills of materials from the design department converge with the orders from the sales department. Furthermore, the ERP system generates the quantity, capacity and resource planning from this.

ERP data (examples):

- Manufacturing: Planning of material requirements and production as well as quality

- Sales: communication prospects & customers, offers, orders

- Design: product development, parts lists

- Procurement: Inquiries, contracts

- Finance: accounts payable and receivable, financial reports

Juxtaposition:

When ERP and PDM

not know about each other

In many companies, ERP and PDM systems already integrate data from the life cycle of a product. Be it bills of material (BOM), master data of articles or material or parts master data. Often, however, not up to date or fully reconciled on both sides.

Then unnecessary and dangerous redundancies or misinformation with significant consequences can be the consequence.

With each other:

When ERP and PDM

speak the same language

If all employees can access exactly the same data, this holds enormous potential:

- Improved information flow

- More efficiency for higher productivity.

- Coordination, for example between production and procurement or sales, is no longer necessary.

- Redundancies due to manual entries are excluded

- A lot of manual rework, usually in the ERP system, is eliminated

- Savings in personnel costs

- Product quality can be better monitored.

With ERP and PDM gradually to PLM?

For more efficiency while reducing costs, digital solutions are needed to organize product information, processes and activities. Depending on the size of the company and its objectives, different paths lead to the goal:

- The implementation of a PLM system as a self-contained overall solution.

- Linking or expanding, at best, familiar systems already in place.

Elaborate:

The Egg-Laying Wooly Pig

A PLM system covers all phases of the entire product lifecycle (conception – design – construction – production – marketing – sales – after sales) within a closed system. In this respect, it is obvious that such a PLM system is complex and also cost-intensive. Moreover, it entails a considerable company-wide introduction and conversion effort. In our view, such solutions are oversized or unsuitable for SMEs.

Note: The terms PDM and PLM are often used synonymously or mixed (“PDM-PLM”) – by users and also software manufacturers.

Build on existing systems

In most cases, an ERP and/or PDM system is already in place in many companies and is fully or partially linked via an ERP coupling. Thanks to the experience gained in this way, employees today know very well what they want and what they do not want. What could be more obvious than to build on this? Optimize individual systems or their interconnection.

In this way, a complete PLM concept is certainly not yet created. In any case, however, a first major, valuable step in the right direction. After all, PDM and ERP are the most essential components of a PLM system.

Practice tips:

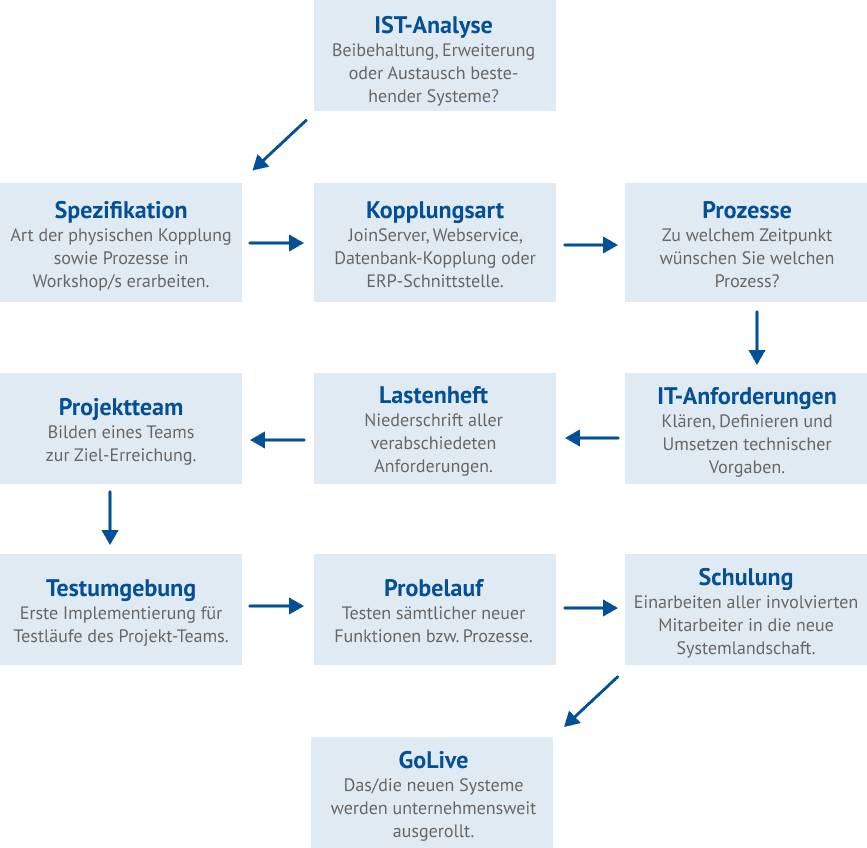

Short roadmap to ERP-PDM coupling

Overview:

Details about the ERP-PDM coupling:

Coupling type: Which coupling do you want?

What is meant is the physical coupling. GAIN Collaboration provides you with four coupling types.

Physical couplings differ in terms of how they are implemented, how they are used, your willingness to invest, and other influencing factors.

Sample questions:

- Do you want bidirectional data exchange?

- Would you like to be able to perform queries from one system to another? For example, query the stock level of an ERP article from the PDM system.

- Should (be able to) keep documents such as drawings in PDF format as attachments to articles in the ERP system?

- Which system should have sovereignty in your company when it comes to article creation?

- Should part numbers be generated manually or automatically?

- Should a number range be defined for an automatic part number in the PDM system?

- Should articles be revisable in the ERP system? Or in other words: Do several versions of an article with attached bills of material exist in the ERP system? Or should only the version, the index change?

Define processes: Develop your desired processes

Define at what time which process should be executed. What should happen when, for example, an article is created? Or if there is a change, copy, revision, or even a status/condition change?

And: In which processes, which events, do both systems form an intersection? Where do processes meet?

What should happen (sample questions), …

… when an article is newly created or copied in the PDM system?

Should the article creation or copy then also be created automatically in the ERP?

… when a document is changed that belongs to an article in the PDM system?

What information should then be matched from the document to the PDM article? The material, the weight or designations? And: If the article is already managed in the ERP system, should it be updated there at the same time?

… when the CAD BOM of a document belonging to an article in PDM changes?

At what point in time should the parts list of the PDM article or the ERP article then be updated? Should the update be automatic or manual?

… when the status of an ERP article changes?

Should the status of the PDM article then also be changed? Should the ERP status have an influence on the PDM article status? If so, what is the impact on related documents?

Technology: IT requirements and specification

Once the physical coupling as well as the processes have been defined, the requirements for the technology arise.

Depending on the coupling method, some technical points have to be clarified, defined and implemented on the part of the IT infrastructure:

- Do drives or accesses in the network need to be adjusted?

- Which permissions on databases and, if applicable, cloud or FTP servers need to be set up?

- Under which users are processes running and which permissions are required?

- Are storage capacities sufficient, for example, at transfer directories?

- Is it necessary to purchase additional hardware and software?

- Where are settings to be made in firewalls under certain circumstances?

The guide: The specifications

All definitions and specifications made are incorporated into a specification sheet. This describes the individual specifications in as much detail as possible. The requirement specification is the guideline for the implementation of the coupling. And ultimately also the basis for a final offer, for the final costs.

The project team

The project team is responsible for all tasks related to the new implementation: Planning, implementation, corrections & optimizations and – after training – the subsequent support towards colleagues.

Team members are different groups of people or groups:

- You, the customer or user

- The customer’s IT department or external IT service provider

- The PDM system house or the manufacturer of the PDM system

- The ERP system house or the manufacturer of the ERP system

- An IT system house, provided that the entire IT is outsourced

You should assign at least one person from each group to the project team that deals with the coupling topics. Each person with their area and across the board with others on the team.

ERP PDM coupling …

Your 1st step to GAIN Collaboration. Order a free demo:

Or do you have any questions

to GAIN Collaboration?

Please contact us: +49 521 967 613 – 0